Pre-Painted Steel Cladding Integral to the North

The new Aquatic Centre in Iqaluit, Nunavut, has revitalized the community and helped to teach another generation of residents how to swim. Joshua Armstrong, architect and Iqaluit office manager for Stantec Architecture in Iqaluit, had his work cut out for him when he was hired to spearhead the project in 2013. The Iqaluit Aquatic Centre was completed in December 2016.

“It’s an aquatic centre first with community centre elements and

a fitness facility. It’s Phase 1 of a long-term plan to increase

recreational facilities in the community,” he explains. “Since

it opened, the response has been overwhelmingly positive.

The Centre gets a lot of use.”

Stantec’s client for the job, the City of Iqaluit, had previously

leased a small pool from a developer, but this pool had been

closed for four or five years.

“There is a generation of young children who didn’t have a

community pool, that didn’t know how to swim – this facility

is changing that in a hurry” says Armstrong. “We got a strong

sense from the client that the new Centre needed to be evocative of the landscape and the culture of the community. They wanted it to be a unique facility, there aren’t many of these types of buildings in the Arctic.”

In addition to the usual challenges of building in such a

harsh climate, Armstrong and his team faced another hurdle

as well: the proposed site for the new Centre was polluted.

“The site has a history, there used to be a nursing station

where this building sits now and their generator had leaked

oil which, with other polluting sources, left a brownfield site.

Foundations design was critical to addressing permafrost

conditions and remediating the site.” he says. “We lifted the

building up and supported it on steel columns that were pinned to bedrock, leaving a space between the building and the ground to allow for snow passage, to protect the melting of permafrost and to de-pollute the site in a passive way.”

Most of the building was constructed of steel, which is

prized for its durability and low-maintenance in the north.

“On the exterior we used a lot of GalvalumeTM coated steel

cladding. It’s a low-maintenance material proven to be quite

good in the north. We have a harsh climate, and the sun and wind are very hard on materials,” says Armstrong, adding that they had to take special care with the treatment of the steel. “aquatic centres have high humidity and chemically treated water, which has a corrosive effect on steel if the steel isn’t addressed properly.”

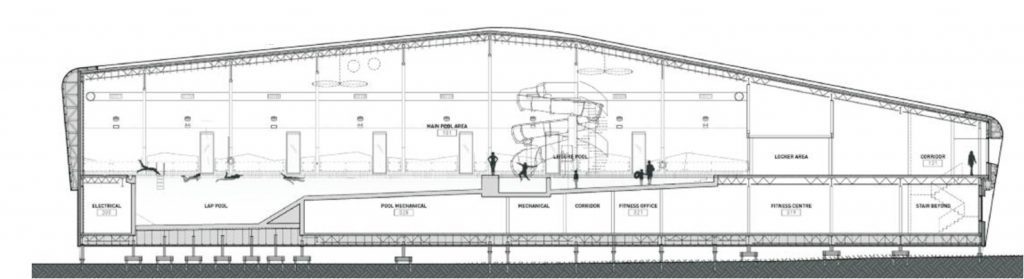

Load-bearing steel studs, rebar, steel decking, with both prepainted and unpainted AZM150 Galvalume® steel wall cladding and roofing were also used in the construction. “The most unique thing about the pool is that it’s not in the ground. It’s on the second floor,” Armstrong says.

“The pool design is minimalist to evoke the ice forms – we have ice and water here and the two are always intermingling.” Since the community of 7,000 people has three official languages, the team developed a graphic language to use throughout the building to eliminate the need for a lot of text on signage.

“In addition to the exterior, the colour is inside the building.

We wanted people to enter a whole new environment when

they walked inside,” says Armstrong. “It speaks to the unique

place that it’s in.”

The central vision of the Iqaluit Aquatic Centre was to create a universally accessible space, while promoting healthy and active living and creating a centralized aquatic facility that acts as a hub for Iqaluit’s recreational culture.

As with the Nunavut Justice Centre, shown here, in the background, Galvalume steel cladding is an Integral part of the Aquatic Centre’s exterior envelope.

Front entrance exhibiting both Agway Metals hidden fastener .76mm (.0299”) pre-painted AZM150 Galvalume steel, coloured Heron Blue QC6079 Weather XL as well as Vicwest Steel’s pre-contoured 22mm (7/8”) corrugated AZM150 Galvalume cladding.

DESIGN AND CONSTRUCTION TEAM

OWNER:

City of Iqualuit

ARCHITECT:

Stantec Architecture 867-979-0555

STRUCTURAL ENGINEER:

Adjeleian Allen Rubeli (AAR) Limited 613-232-5786

STEEL CLADDING SUPPLIER:

Moulures 200 Inc, QC 418-596-2606

CLADDING PRODUCERS:

Agway Metals Inc. 800-567-2582

Vicwest 800-567-2582

CLADDING INSTALLER:

Kudlik Construction 867-979-1169

EXTERIOR WALL CLADDING

Agway: 22.2mm (7/8”) corrugated, .76 mm (.0299”)

AZM150 Galvalume

Agway: Hidden Fastener panel: 305mm x .76mm (12” x .0299”)

coloured Heron Blue QC-6079 – Weather XL

Vicwest: Pre-contoured (for curved surfaces):

AZM150 Galvalume for the roof

thickness: 0.76mm. (.0299”)

STEEL DECK:

Deck typically 965mm x .76mm (38” x.0299”)